A Letter from Entex’s VP of Engineering, Jeff Danner

Imagine for a moment that you are a heterotrophic bacterium and you have the good fortune to be floating amidst municipal sewage in a wastewater treatment plant. You have a steady supply of food, someone is blowing fresh air through your water and also is looking after your needs on things like pH and nutrients. For the next twelve hours or so, until you devolve into your offspring via cell division, life is rather good. However, in spite of your peace and tranquility, you don’t know too much about your new abode. Are you in an activated sludge plant, a sequencing batch reactor, an oxidation ditch or, perhaps a humble lagoon? Below, I will try to convince you that you don’t really care.

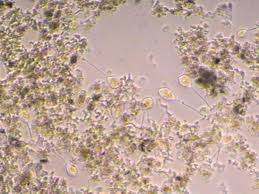

Photo credit: Paul Olander, VT Department of Environmental Conservation

A conversation that I have quite frequently goes something like this:

-

- Engineer/Operator:

“We’ve got some lagoons that we are now going to use for storage/EQ and are going to build a new mechanical plant for treatment. What can Entex provide?”

-

- Jeff:

“We’d be happy to help, but can you tell me why you have decided to abandon the lagoons? We can improve their performance in a number of ways including adding biomass with fixed film modules, improving aeration, creating anoxic zones for denitrification, etc. That would certainly be more cost effective. What are you trying to achieve?”

Thinking of yourself as a bacterium again, all you want to do is eat, breath, expel your waste products, and pass along your DNA. There is no particular reason that you can’t do this in a lagoon. Let’s consider the shortcomings of lagoons as treatment basins, especially the ones that encourage people to consider abandoning them and how those shortcomings can be addressed.

Most lagoons do not have recycle of return active sludge, so the population of microorganisms per unit volume is quite a bit lower than in a typical mechanical plant. To overcome the lack of biology, you make the lagoon really big to allow for days or even weeks of residence time so that your biological population has time to get the job done. A better solution is to increase the amount of beneficial biology in the lagoon by installing fixed film modules with high surface area media thereby providing a place for biofilms to grow, such as Entex’s Webitat, WavTex, or BioBloc modules.

Another issue is that lagoons often struggle with getting enough dissolved oxygen. Here again, size helps. The large surface area of the lagoon allows for significant contact with the air above. Many lagoons also use floating, splash-style aerators. These can be effective in shallow lagoons but can be a bit of a maintenance headache since there are many motors out on the water that need to be serviced. Converting to a system which introduces diffused air near the lagoon floor such as Entex’s Octopus system can improve DO, reduce electricity costs, and facilitate maintenance by utilizing easy-to-access, on-shore blowers.

Lagoons often struggle with nitrification in the winter when the water gets cold. Here again, fixed-film modules can help. They increase the number of nitrifiers in the lagoon and the design of the modules places the biology near to the warm air from the blowers. Sort of like a space heater for your bugs. These dynamics allow lagoons with fixed-film modules to nitrify all year long.

The advantages of keeping and upgrading your lagoon are clear. With no new space, no new tanks, no new pipes and so on, the cost is much, much lower than building a new mechanical plant, which is much easier on the budget. An additional benefit is the simplicity of operations, saving money on an annual basis. So before you as the bacterium are forced to relocate, send us a note at info@entexinc.com and let’s talk about remodeling your current home.