The vast majority of aerated lagoons employ floating mechanical aerators to supply mixing and dissolved oxygen. While these aerators do have the advantage of relatively low upfront capital, the cost of the electricity to run them can be quite high. In addition, maintaining motors which are floating in the middle of a lagoon is rather inconvenient and, in cold weather locations, ice buildup on the motor housing can cause them to tip over.

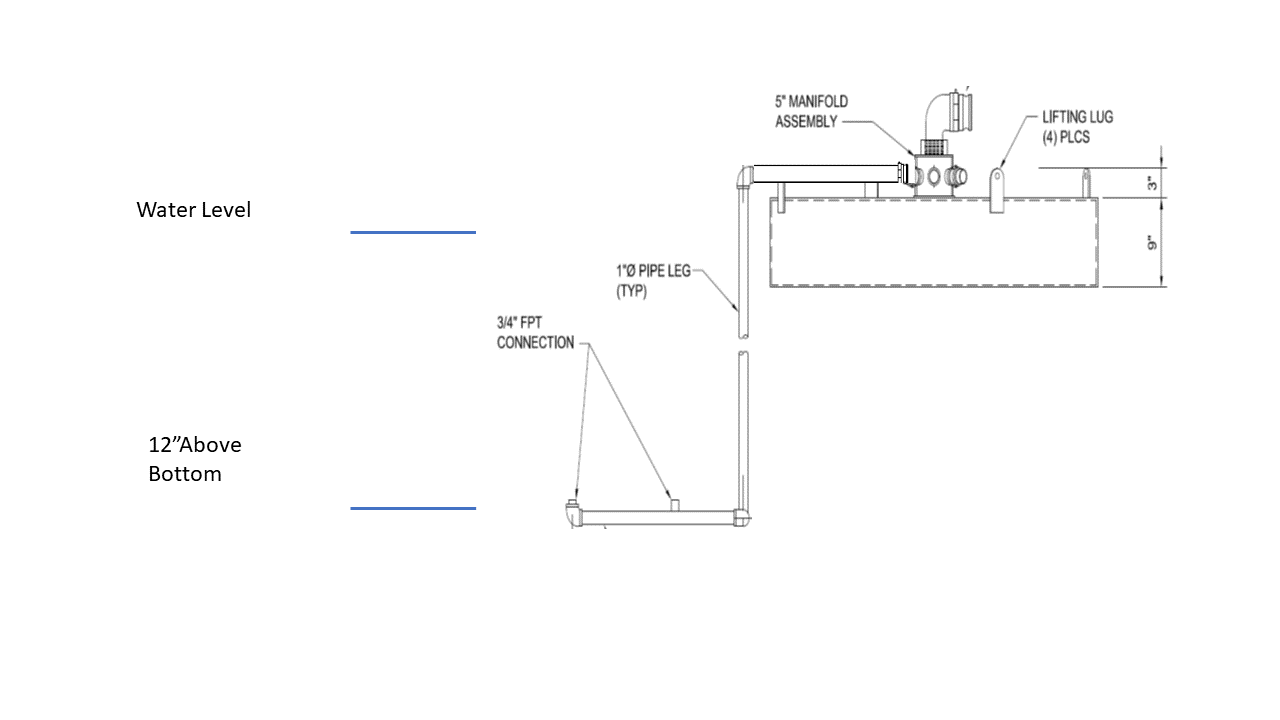

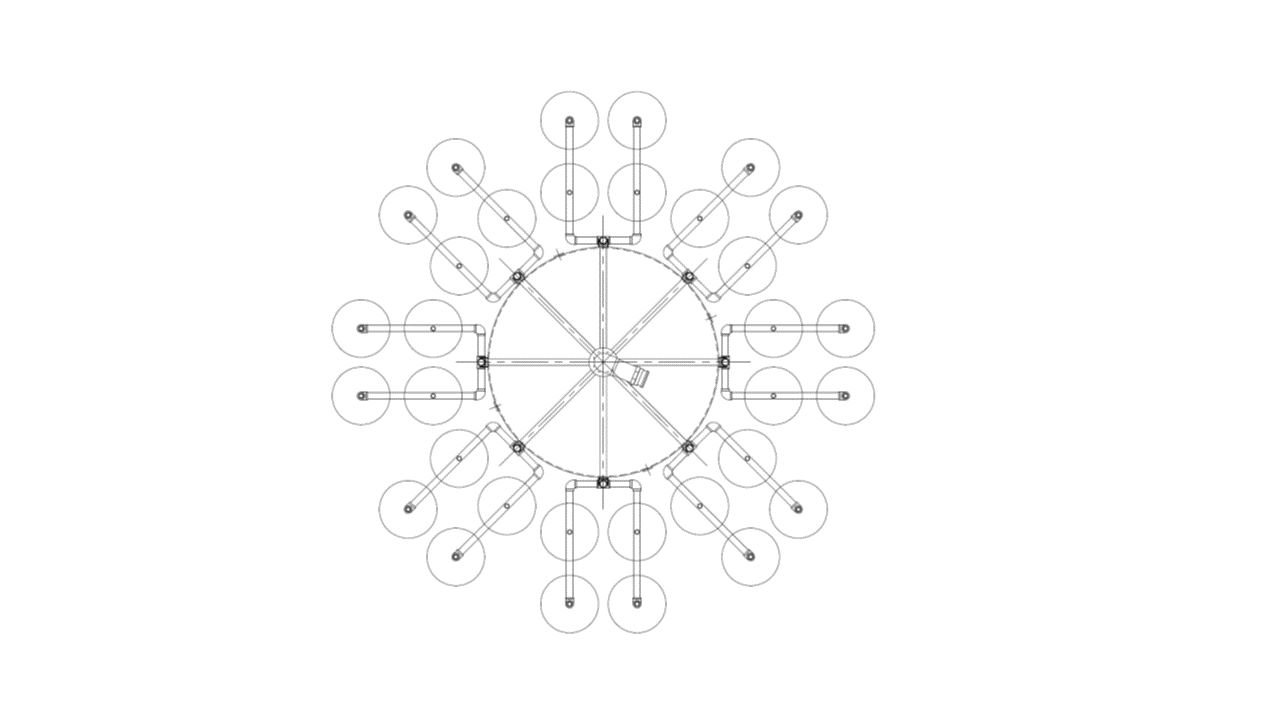

Entex’s Octopus Floating Aerators can provide significant cost savings. The graphics above illustrates the key features of the Octopus. Air is supplied to a manifold at the top of the modules via floating hose from blower(s) located on the shore. Then air is distributed to the unit’s 8 drop legs that have diffusers attached just above the lagoon floor. This arrangement provides improved oxygen transfer efficiency and better mixing with far less electricity than floating mechanical aerators. Further, the blower motors are on shore, making maintenance much easier, and the low center of gravity of the Octopus ensures that they will not tip over even in coldest environments.

The cost savings of the Octopus system versus floating mechanical aerators is dependent on the amount of actual oxygen required (AOR) as well as the depth of the lagoon. As a typical example, consider a lagoon which is 10 feet deep (about the maximum for mechanical surface aerators) with six 7.5 Hp floating mechanical aerators. The site elevation was assumed to be 500 ft above sea level. The table below calculates the AOR and the power consumption.

Next, we determined the power requirements for an Entex Octopus system to provide the same 1,620 lbs O2/day of AOR. In a 10 foot deep lagoon, the diffusers at the bottom of the Octopus drop legs would be positioned at a depth of 9 feet. The necessary 1,620 lbs/day of AOR can be provided with 4 Octopus modules suppling 361 scfm of aeration from a 14.9 Hp (11.1 kW) blower. Thus, the Octopus system can provide the same AOR as the mechanical floating aerators while drawing 22.4 fewer kW of power. Over the course of the year, the total energy savings is 196,623 kWh!

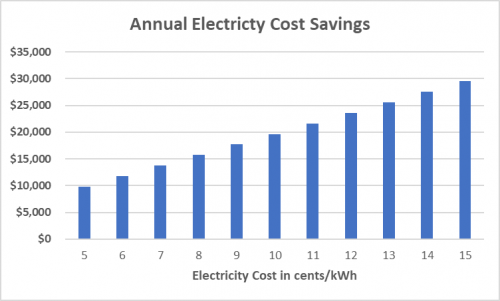

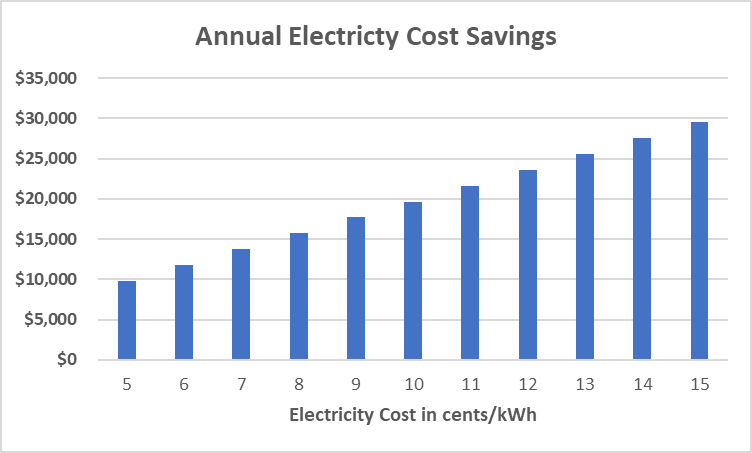

Depending on the electricity cost for the location, the savings can be quite substantial. The graph below shows range of potential savings. Note that the energy savings scale with the size of the system.

Replacing mechanical aerators with Entex’s Octopus system (or outfitting a new lagoon) can provide a rapid return on investment and also make life easier for your maintenance staff by keeping the motors on shore. In some locations, additional incentives for reductions in electricity use are available from the power company.

If you would like an evaluation of the how Entex’s Octopus system can improve operations and your facility, contact us at info@entexinc.com.