A letter from Entex’s VP of Engineering, Jeff Danner

When friends or family ask me how a wastewater treatment plant works, I often start by telling them that the process is fundamentally the same as what happens in any pond, river, lake, or stream. The bacteria eat the waste while using up oxygen and they do it faster if it is warmer. Given that we know that the most important parameters in treating the waste are the amount of bacteria, the amount of oxygen, the amount of time, and the temperature, we can design a treatment plant that does what a natural body of water does, but much faster by increasing the inventory of bacteria and blowing a lot of air through the water. Note, at this point the friend or family member who asked me the question, is likely regretting it.

Since you are here on Entex’s new page, I’ll assume you have more interest in these topics than a cousin of mine at a family dinner, so I’ll move on to lagoons. Lagoons are an interesting – at least to me – approach to wastewater treatment. In the simplest form, a lagoon is just a pond, doing what a pond does. If we look at our four key parameters of wastewater treatment, a simple facultative lagoon is lean on bacteria population, and limited in oxygen input but counterbalances this by being large and, thus, having plenty of time for treatment. Further, the temperature changes with the seasons, so in the wintertime, everything slows down, and nitrification falls off significantly or stops altogether.

To increase lagoon treatment capacity, the first step is usually to increase aeration, either with floating aerators that agitate the surface or with a system like Entex’s Octopus floating aerators which utilize diffusers located on or near the floor of the lagoon. This approach allows the lagoon to treat more waste, especially more BOD, without dropping to low levels of DO which can result in odor and/or foam formation. However, just adding aeration generally will not allow for year-round nitrification in colder climates.

Year-round nitrification in cold-climate lagoons requires increasing the inventory of bacteria. There are three approaches generally used for this. Some systems use a clarifier to recycle activated sludge back to the lagoon, some systems will install a post lagoon MBBR for ammonia polishing, or the lagoon itself can be upgraded by installing fixed-film modules such as Entex’s Webitat, WavTex, or BioBloc systems. The fixed-film module approach is usually the low-cost option since no new land must be cleared and no new tanks need to be constructed. You simply place the modules in the lagoon and supply air from on-shore blowers via a manifold of floating air hoses.

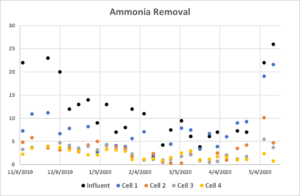

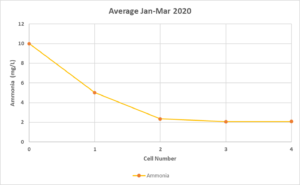

As an example, the town of Rockford in Northwest, OH – certainly qualifying as cold-climate – needed to achieve year-round nitrification. Prior to this upgrade, the 0.45 MGD system consisted of two lagoons in series. In 2019, the two lagoons were each subdivided into two cells, for a total of four cells, and along with the addition of floor mounted fine bubble aerators, Entex installed seven Webitat modules, four in cell #2 and three in cell #4. The graphs below show the cell-by-cell ammonia data from November of 2019 through May of 2020 as well as the average ammonia concentrations from January through March of 2020.

As can be seen from observing the data for Cell #4, effluent ammonia was below 5 mg/L all winter long. Further, the set-and-forget nature of a Webitat lagoon system allows this performance to be achieved with no maintenance tasks other than looking after the blowers.

If you would like additional information about upgrade your lagoon with one of our fixed-film systems, contact us at info@entexinc.com.