Entex is pleased to announce our introduction of a major MBBR innovation with the launch of our patent pending BioTexTM system. BioTex is a major evolution providing industry leading cost/performance metrics.

The BioTex MBBR is the second implementation of our highly successful EnTextile biofilm media following its demonstrated success in our patented WavTexTM system. EnTextile’s woven, three-dimensional matrix consists of two exterior sheets with hexagonal openings, connected within by a multitude of fibers that provide exceptionally high effective surface area for biofilm growth. The media is fine-tuned to match the specific treatment needs by manipulating the size of the hexagons, the distance between the two surfaces, the density of connecting fibers, the specific gravity of the media, and whether the media is provided as sheets (WavTex) or free floating pieces (BioTex). A unique and valuable feature of EnTextile is that the spacing between the sheets is set such that, even within an aerated tank, an anoxic zone is created within the interior of the media, which allows for a high degree of simultaneous denitrification. This novel and groundbreaking feature has allowed our EnTextile media to provide nearly compete total nitrogen removal within a single, aerated tank, proving a significant cost savings to customers by eliminating the need for a separate anoxic tank/basin.

The version of EnTextile used in the WavTex system is woven from polypropylene fibers, with a specific gravity low enough to float with biomass under active aeration and provided in sheets. These sheets are tethered to a frame on the bottom which has an integrated coarse-bubble aeration grid. As a result, WavTex modules have an array of self-buoyant sheets which undulate freely and scrape against their neighbors due to the influence of the aeration. The WavTex design is well suited to both lagoon operations and SFF and IFAS upgrades in rectangular tanks.

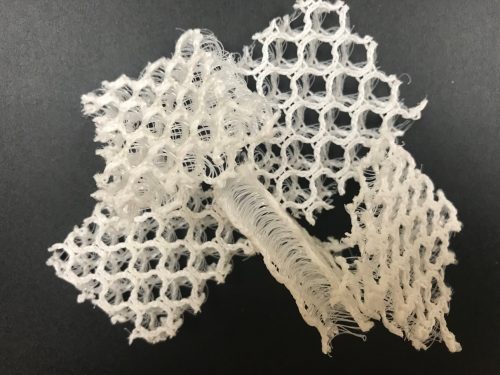

The EnTextile media utilized for the BioTex system maintains the high surface area and three-dimensional structure of the buoyant sheets used in the WavTex, but is woven from high-density polyethylene fibers, giving it a specific gravity of 0.96. This is exactly the same HDPE material and specific gravity used in traditional MBBR systems. The BioTex MBBR system utilizes pieces of EnTextile media which are approximately 25 mm x 25 mm x 10 mm in size. From a design and operations perspective, the BioTex media is a substantial upgrade to traditional, extruded MBBR media in both price and performance and also brings with three critical and valuable advantages:

- With a specific surface area of 1,350 m2/m3, it provides much more biologically active surface area at far lower fill percentages than traditional, extruded MBBR media.

- Like the sheets on the WavTex module, the EnTextile pieces used for BioTex maintain an anoxic interior allowing simultaneous denitrification to occur within aerated tanks.

- The flexible media pieces will not break as can be the case with more brittle extruded media even when used within an anoxic stage with a mechanical agitator.

BioTex MBBR systems can be used for any application where a traditional MBBR is being considered.

Need to add treatment capacity to an existing facility? Want to maximize removal in a small footprint? Need a more cost effective MBBR system? Contact us at info@entexinc.com to see if a BioTex MBBR can help you to achieve your goals.