Conventional activated sludge uses a suspended biomass to provide a flexible and efficient treatment system. While some AS systems use complete mix basins, a plug flow process with longer narrower basins is more common today. Similarly, while some AS systems still use older coarse bubble diffuser systems, most updated systems use fine bubble diffuser systems to maximize energy efficiency. There are step feed variations and tapered aeration variations, but normal systems have from 3 to 8 hours hydraulic retention time and are limited by the clarifiers as to how much solids may be maintained in the system. It is this MLSS limited factor that Entex’s fixed filmtechnology addresses.

To remove more organics, the system requires more biomass. To address nitrification, the SRT is increased to allow slow growing nitrifying organisms to proliferate. To denitrify, adding an anoxic zone consumes space otherwise used by the aerobic basin. Biological phosphorus removal is accomplished by adding an anaerobic zone, which also uses more aerobic tankage.

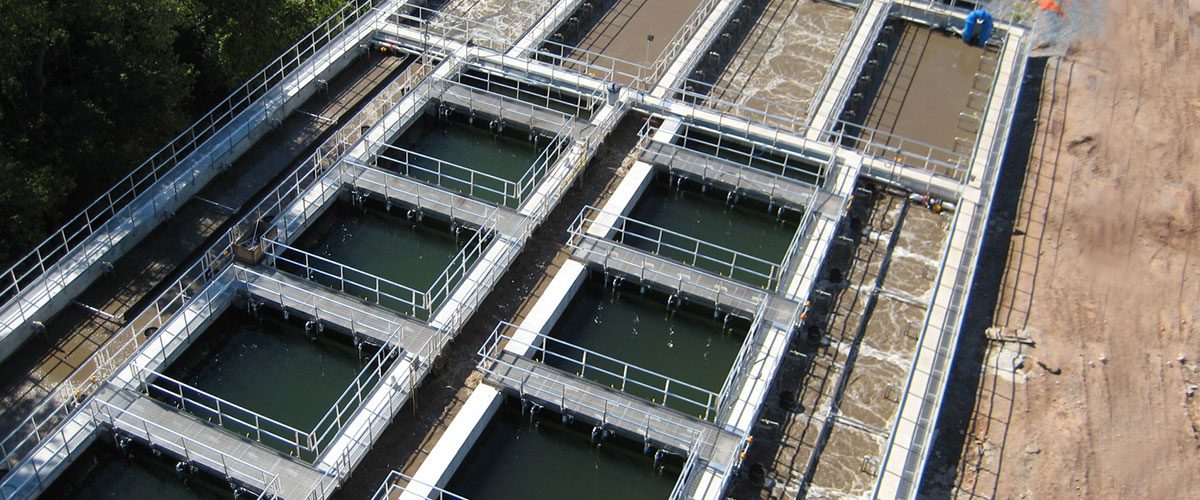

Since bottom-loading clarifiers limit the MLSS in the system, the traditional method of building more aeration tankage and more clarifiers worked. However, this expansion is extremely expensive and consumes limited plant space. With Entex’s attached biomass technology, we can typically more than double the biomass in a given geometry without overloading clarifiers.

Entex provides solutions to upgrade Activated Sludge systems, including BioWeb and Webitat fixed media systems that allow re-use of existing fine bubble diffusers.

Download Whitepapers and Case Studies

Download: Demonstration and Full Scale Results of a Plant Upgrade for BNR