A Letter from Entex’s VP of Engineering, Jeff Danner:

On June 9th Entex was issued a patent for our WavTexTM fixed-film secondary treatment system and innovative EnTextileTM growth media, System and Method for Biologically Treating Wastewater Using Low Density, High Surface Area Substrates. It represents a significant step forward in single tank/basin nitrification and denitrification which, as I outline below, is another step forward in the long line of progress in the wastewater treatment industry.

Although it is not generally viewed as being particularly glamorous, I am quite proud to work in the wastewater treatment industry. From the sewers and aqueducts of Imperial Rome to today’s high-tech water recycle and reuse systems, wastewater treatment is a story of continuous improvement which has made a contribution to human well-being on par with antibiotics and vaccines. Slowly but surely over the centuries, we have made our water cleaner and cleaner by removing solids, dissolved organics, nutrients, and pathogens. But we still have more work to do.

The release of ammonia from wastewater treatment systems into lakes, ponds, rivers, and streams is well-known to result in damaging algae blooms. This effect can be mitigated to a degree, but not completely, by oxidizing the ammonia to nitrate (NO3). Therefore, a key next step in our industry’s long journey in improving water quality is removing nitrates through denitrification to convert it into harmless nitrogen gas efficiently.

The process for denitrification is well known. You simply oxidize ammonia to nitrate and then introduce the nitrate to a tank or a zone with low dissolved oxygen and a carbon source as food for the microbiology and Mother Nature will take things from there. The true challenge of denitrification is the economics.

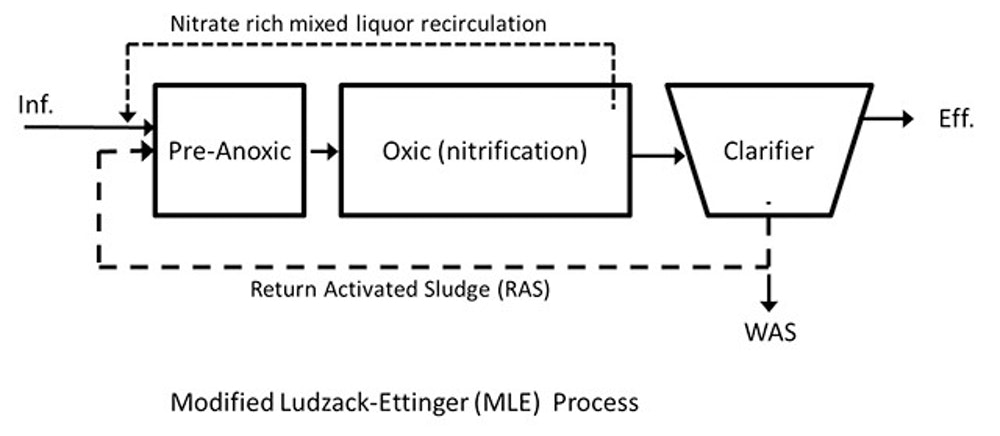

The traditional approach involves pumping internal mixed liquor from the back of the aeration tank to a anoxic tank in the front of plant at a rate of 200-400% of influent flow as shown below.

This approach requires large pumps, expensive piping, and an additional tank. Due to the significant expense of this approach, a number of alternative methods have been developed to facilitate low-cost, single tank/basin nitrification. Several examples are listed below.

-

- Activated Sludge with Intermittent or Zoned Aeration

This approach uses a traditional activated sludge design, but different sections of the tank are aerated at different times. This is done in an attempt to create transient aerated and anoxic zones within the tank. This approach has been successful but can have difficulty in sustaining the proper dissolved oxygen (DO) gradients and can lose nitrification in the winter in colder environments.

-

- Annamox

This approach utilizes specialized bacteria which can both nitrify and denitrify all within an aerated tank. This approach has also been successful. However, it requires careful control of the conditions within the treatment facility to prevent other microorganisms from taking over.

-

- Fixed Media Modules Run in Cyclic On/Off Mode

This is an approach that Entex has used successfully in the past in which our Webitat modules were placed in an existing basin. At any one time half the units are being aerated and the others are not. This approach creates clearly defined aerated and anoxic zones and can support nitrification at bulk water temperatures as low as 4 ◦C.

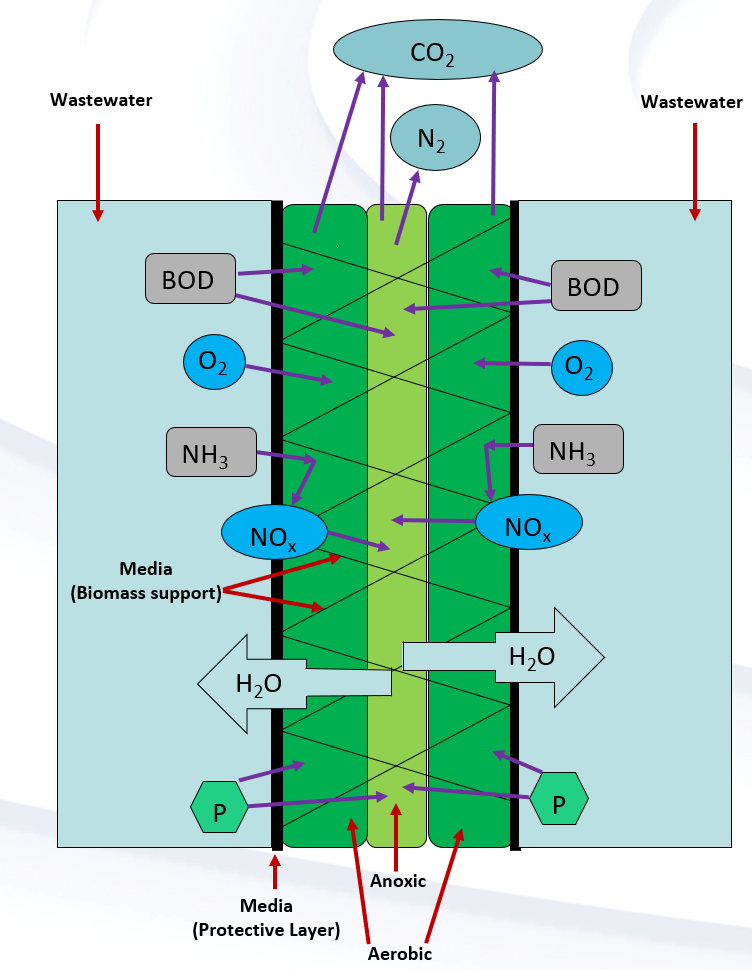

The invention of our patented WavTex system represents a further and noteworthy improvement in single tank/basin nitrification and denitrification. The graphic below shows a cross-section of the novel EnTextile media.

The three-dimensional design of the EnTextile media creates gradient of reduced DO as the liquid moves further towards the interior of the media. This allows both Biological Oxygen Demand (BOD5) removal, nitrification, and denitrification to all occur within a single tank/basin. The anoxic zone within the interior of the media sheets is present even when the bulk liquid has DO concentrations near to the saturation point.

The EnTextile media also self-buoyant and flexible. When installed, it is tethered to a rack on the bottom which also houses an integrated coarse bubble aeration system. The bottom rack can attach to a concrete floor, sit on the floor with ballast, or hang down from a floatation bracket depending on the needs and geometry of the system. When the media sheets are immersed in water, they stand up and wave back and forth, evoking the image of a seaweed bed and proving the inspiration for the WavTex product name. The flexing and scraping of adjacent sheets help slough off excess biomass.

The WavTex system can be installed in nearly any wastewater treatment system, IFAS, lagoons, SBRs, etc. As we continue to install more systems, I take pride in know that we are preventing more and more nitrogen nutrients from entering our watersheds and the Entex is make it contribution to our long journey towards cleaner and cleaner water.

If you would like to learn more about how our WavTex system can help you to meet your needs, send us an email to info@entexinc.com.