While the construction of wastewater facilities that treat tens of millions of gallons a day attract a lot of attention, the vast majority of wastewater plants are much smaller and serve small communities, housing developments, industrial facilities, resorts, etc. At first glance, these smaller, packaged plant facilities seem quite similar to one another. However, due to differences in influent – particularly for industrial sites – and effluent requirements each facility needs to be custom designed.

Entex Technologies can be a convenient supplier of all equipment and support for your full packaged plant from influent to effluent including:

- screening and grit removal

- equalization

- blowers

- IFAS treatment for process resiliency and footprint minimization

- solids separation

- tertiary filtration

- disinfection

- reaeration

- controls and instrumentation

We can also provide remote monitoring and follow-on service contracts if desired.

Depending on process needs, geography, topography, and regulation, an Entex packaged plant can come in several configurations. Shown in the pictures below are: a segmented poured in place concrete tank for which Entex supplied the equipment, a series of free standing modular tanks, and a complete system in a rectangular tank which can be delivered on a truck.

All Entex packaged plants include IFAS for biological treatments utilizing either our WebitatTM or WavTexTM technologies. Including IFAS reduces footprint, increases process resiliency to upsets, enhances nitrification and denitrification, reduces sludge production, and improves solids settleability.

For packaged plants with TSS limits or which include UV sterilization, a FlowTex drum filter is installed.

The drum filter is a highly cost and space efficient approach to remove solids larger than 10 micron. It can either be configured as a clarifier insert or in a stand alone tank.

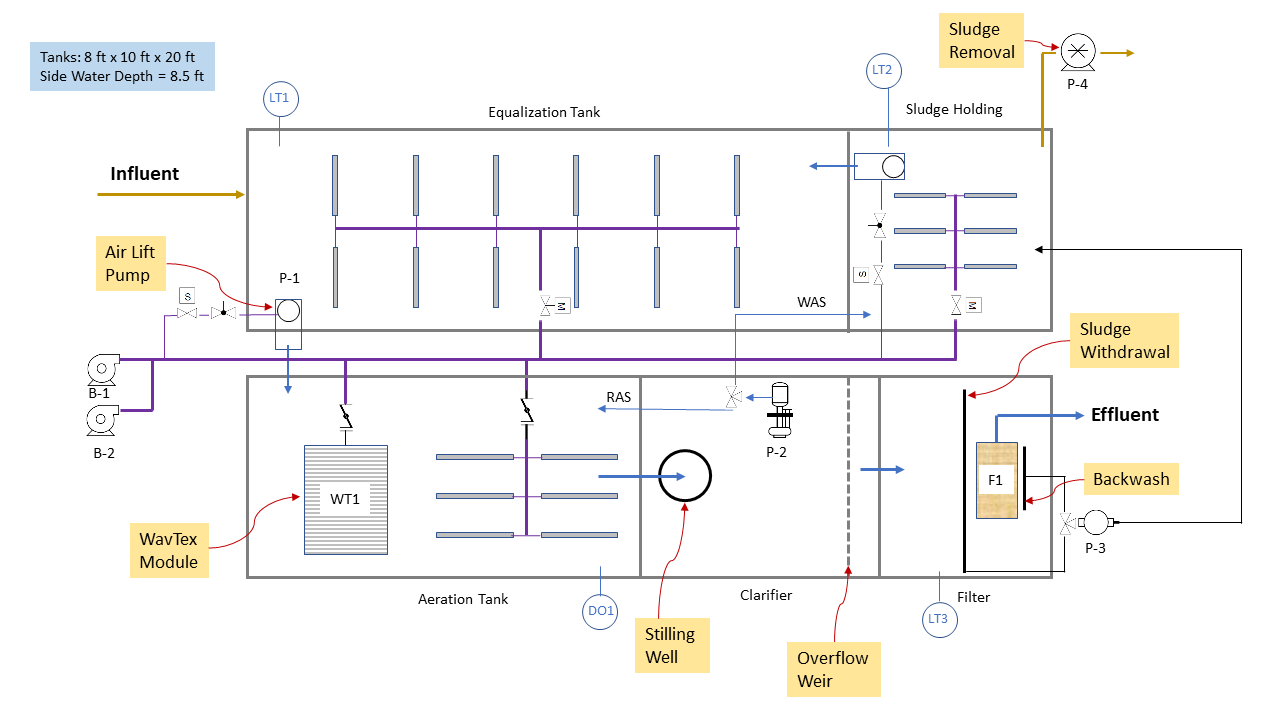

A process flow chart for a typical Entex Packaged Plant is shown below.

Entex’s packaged plants are reliable, flexible, modular, space efficient, and minimize installation costs. So if you need a complete wastewater solution, reach out to us at info@entexinc.com.